Introduction to Kraft Pulping and Bleaching Course

Introduction to Kraft Pulping and Bleaching Course

Introduction to Kraft Pulping and Bleaching Course

TAPPI HQ

Tuesday, August 06, 2024 to Wednesday, August 07, 2024

The Introduction to Kraft Pulping and Bleaching Course is one of TAPPI's most successful annual training events, offered for more than 12 years!

The overall course objectives are to:

- Expand your overall understanding of kraft mill operations

- Broaden awareness of how one part of the process impacts other operations

- Demonstrate the effect of process variables on kraft pulp quality

- Build your confidence for effective interaction among new and experienced engineers and operators

- Lay the initial foundation for you to troubleshoot product and process problems

For suppliers and others at the mill, this course will help you:

- Understand product performance and pulp quality by knowing the differences in wood and fiber variations.

- Provide the basics in troubleshooting, optimization and control by better understanding "why things happen" in pulping and processing - the variables affecting pulp quality.

In helping you learn these outcomes and more, Course Chair, Dr. Michael Kocurek, shares his collection of more than 1,000 visuals during the Course Schedule, which you'll have for review later at the mill.

Attendees will receive the visuals in a printed Notebook, and in color on a PDF flash drive.

This is the most comprehensive two-day introductory to intermediate-level course on Kraft Pulping and Bleaching in the industry.

Introductory-Level Content (45%)

This course will have Introductory level content that includes:

- Overview of Processes & Technology (“what happens”)

- Vocabulary and Terminology

- Equipment Overviews & Descriptions

- Product Properties

- Effects of Processes on Products

- Effect of one part of the mill on other parts

Intermediate-Level Content (45%)

This course will list and discuss various process variables, the “why things happen,” and other intermediate topics. The curriculum also provides a foundation for the advanced-level topics below.

Advanced-Level Content (10%)

This course will not include topics in depth, such as mill-specific troubleshooting; equipment design, operation, process control, etc. The curriculum will cover some mill operation and optimization examples.

Course Learning Objectives:

Kraft Pulping and Processing

- Become familiar with pulping and bleaching terminology

- Increase knowledge of the most common pulp properties/tests

- Understand wood fiber and wood and chip preparation

- Learn the major types of equipment (Batch & Continuous Digesters) used in kraft pulping

- Gain an overview perspective of the primary operations and reactions that occur in the digesters between wood and pulping chemicals

- List several major pulping variables and gain an overview of major kraft pulping trends

- Understand pulp processing (washing, screening, cleaning) and by-product recovery basics

Bleaching

- Increase understanding of the bleaching sequences, variables, and bleaching reactions

Environmental

- Build greater awareness of pulp mill environmental challenges

Pre-Course Survey

In order to build the best foundation for more advanced topics that are most important to you, Dr. Kocurek conducts a pre-course survey to determine:

- What are your specific learning objectives and what would you like to take away?

- What is a specific technology related “hot topic” for your mill or company?

- What process related troubleshooting topic would you like to see discussed as a basic level case study?

Your answers will contribute to some customization, within the scope and available time, to increase the value of the course.

Who Should Attend

The TAPPI Introduction to Kraft Pulping and Bleaching course is ideal for anyone new to the kraft pulping process, particularly process engineers, machine operators, kraft pulp operators and suppliers.

For new employees and those moving to new positions...

- A more rapid, in depth and enhanced completion of their training;

- The ability to learn and gain additional knowledge more easily when interacting with any experienced mill people or suppliers; and

- Having the foundation of knowledge to take on more advanced projects, including troubleshooting both process and pulp quality problems.

For more experienced people...

- Filling in gaps in technical knowledge (we all have some!); and

- The ability to better train new employees.

Take Note!

- Seats will sell out to the first 25 participants to encourage optimum student/instructor interaction.

Attendance Support Materials

We understand it can be challenging to ask for approval to attend TAPPI training events, so we created Attendance Support Materials to assist you with the approval process and in making a strong case for the investment.

Earn CEUs!

TAPPI awards 1.3 Continuing Education Credits (CEUs) for completion of this course.

TAPPI's Professional Development department has been accredited as an Accredited Provider by the International Association for Continuing Education and Training (IACET) since 2006. In obtaining this accreditation, TAPPI has demonstrated that it complies with the ANSI/IACET Standard which is recognized internationally as a standard of good practice. As a result of the Accredited Provider status, TAPPI is authorized to offer IACET CEUs for programs that qualify under the ANSI/IACET Standard.

This course is ideal for anyone new to the kraft pulping process, particularly process engineers and operators.

The small class size, breaks every hour, and lunch are designed for maximum interaction between class participants.

- Attendees help design the course by completing the pre-course Survey that asks “why are you coming to the course,” and what topics you would like covered.

- Dr. Kocurek encourages contact during or after the course to have attendee's questions answered. If he does not have the answer, he involves other experts.

8:00 – 8:50

- Course Overview and Learning Objectives

- Introductions

9:00 – 9:50

Wood and Fiber Raw Materials

- Hardwoods and Softwoods

- Wood Properties

- Fiber Properties

10:00 – 10:50

Preparation of Wood & Chips for Pulping

- Debarking

- Chipping

- Screening

- Storage and Recovery

- Chip Quality

11:00 – 12:00

Preparation of White Liquor

- Chemical Terminology

- White Liquor Chemical Test

- Chemical Recovery Cycle

12:00 - 12:45 LUNCH

12:45 – 1:20

Overview of Kraft Pulping

- Terminology

- Pulp Properties and Tests

1:30 – 2:20

Kraft Digesters and Technology

- Batch

- Continuous

2:30 – 3:20

Kraft Pulping Chemical Reactions

- Delignification

- Cellulose

- Hemicelluloses

- Extractives

3:30 – 4:20

Kraft Pulping Variables and Effects on Properties

- Chip Quality Variables

- AA, EA

- Digester Variables

- H Factor

- Variables affecting Yield

- Variables affecting Strength

- Variables affecting Kappa

4:30 – 5:15

Trends in Kraft Pulping

- Displacement Cooking

- MCC Cooking

- Lo-Solids

- Isothermal

- AQ

- Polysulfide

5:15 Adjournment

8:00 – 8:30

Pulp Processing Overview

- Fiberizing/Hot Stock Refining

- Washing

- Screening and Cleaning

- Oxygen Delignification

8:30 – 9:20

Brown Stock Washing

- Displacement

- Diffusion

- Equipment

- Washing Variables

9:30 – 10:20

Screening and Cleaning

10:30 – 11:20

Overview of Bleaching

- Sequences

- History

- ECF and TCF

- Terminology

11:30 – 12:00

Oxygen Delignification

- Equipment

- Variables

- Reactions

12:00 - 12:45 LUNCH

12:45 – 1:20

Oxygen Delignification (Cont.)

- Equipment

- Variables

- Reactions

1:30 – 2:20

Chlorine Dioxide Bleaching

- Equipment

- Variables

- Reactions

2:30 – 3:20

Caustic Extraction and Other Bleaching Sequences

- E, EO, EP and Variables

- Ozone

- Peroxide

- Enzymatic

3:30 – 4:15

Bi-Product Recovery

- Tall Oil Soap

- Turpentine

- Lignin

- Ethanol

- Acids

- Other

4:15 – 5:00

Pulp Mill Environmental Review

5:00 Adjournment

Note: For participants with later departures, Professor Kocurek will be available for further Q&A and discussion.

Introductory -Level Content (70%)

This course offers introductory-level content that includes:

- Equipment & Terminology

- All major Pulp Mill Fiber Line Processes

- Pulp Quality Properties & Tests

- Effects of Processes on Product Quality

- Effect of one part of the pulp mill on other parts

Intermediate-Level Content (30%)

This curriculum covers various process variables, the “why things happen,” and will provide a foundation for the advanced-level topics below.

Advanced-Level Content (0%)

This course does not cover training topics, such as equipment design, operations in depth, maintenance, process control, or mill-specific topics, such as optimization and troubleshooting.

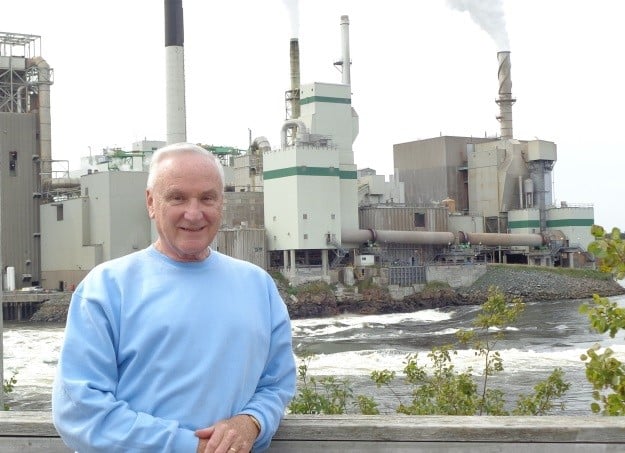

Dr. Michael Kocurek and Tom Holm

Meet Dr. Michael Kocurek

Dr. Kocurek, Professor Emeritus of Paper Science & Engineering at North Carolina State University, is one of the world's most recognized educators in the pulp and paper industry.

His focus is on Pulp & Paper Technology, Linerboard Manufacture, Tissue Manufacture, Paper Properties, and Workforce and Professional Development.

He has taught students and thousands of industry operators and professionals at more than 200 mills and 50 paper industry corporations, government and other organizations, including TAPPI, the Department of Energy (DOE), Environmental Protection Agency (EPA), and the American and Forest Association (AF&PA). Additionally, he has taught undergraduate and graduate students since 1970.

Dr. Kocurek has developed seven distance e-Learning P&P technical courses under a National Science Foundation (NSF) grant at Coastal Alabama.

He is the course chair for TAPPI's oldest and highly ranked short course on Introduction to Pulp & Paper Technology (for 44 years). He is the editor of 11 books, including the recognized Pulp and Paper Manufacture series covering the entire field of pulp & paper. He has authored and/or co-authored 25 video publications, including the Introduction to Pulp & Paper series- again covering the entire field of pulp & paper.

Dr. Kocurek received his B.S., M.S., and PhD degrees in Paper Science & Engineering from the SUNY College of Environmental Science & Forestry, and Syracuse University. He has served as Paper Science Department Head at the University of Wisconsin-Stevens Point, an academic program he founded; and NC State University. He also has served as Executive Director of the Herty Foundation, an authority agency of the State of Georgia. While at Herty, he oversaw a $27 million modernization of the laboratory, creating the largest pilot scale P&P and advanced fiber development center in the US.

His honors include TAPPI Fellow, TAPPI Distinguished Service Award, TAPPI Paper and Board Division Technical Achievement Award; and induction into the Paper Industry International Hall of Fame - an honor bestowed to recognize people who have made preeminent contributions to the global paper industry.

Specifically About This Course

Dr. Kocurek says, "The Introduction to Kraft Pulping and Bleaching Course is the kind of training that offers a view of the entire puzzle, so to speak, rather than a detailed focus on one or two operations. There are few if any other courses that combine this field of focus into one. This is an ideal course for anyone who wants to better understand kraft pulping and bleaching operations and processes, pulp grades and products, and what they can do to enhance their own job performance.”

Tom Holm, Freelance Consultant to the Pulp and Paper Industry

Tom is the owner of Yggdrasil Pulp Consulting LLC, providing process analysis, capital justification assistance, and training services to the Pulp and Paper Industry. He has worked with Buckman International as a global subject-matter expert in pulping and related processes. During his six year tenure, he worked with Sales Associates and their customers in 19 countries. He is the author of a series of global webinars discussing various facets of the pulp industry from pitch control to bleaching enzymes. He has authored several papers and made presentations for World Pulp and Paper, TAPPI, Pulp and Paper Canada, ABTCP and CIADICYP.

He has taught introduction to pulping courses for customers and sales associates alike on four continents and has visited over 150 mills, roughly half of which are in North America. This is his third year as an instructor for TAPPI’s Introduction to Pulp and Paper short course.

Prior to joining Buckman, Tom worked for the Willamette mill in Hawesville, Ky., Weyerhaeuser and eventually Domtar (now Paper Excellence). After working as an intern at Hawesville in 1982, and two summers at the Red River Mill in Campti, La., he remained with the company after receiving his BS in Paper Science and Engineering in 1985 from the University of Wisconsin-Stevens Point. He held various positions at the Hawesville site including a four-year stint as the technical manager of the Kentucky Medium mill until it’s closure, when he returned to the pulp mill. He also managed the corporate PSM audit team and severed as the first chair of the Domtar corporate fiberline manager’s roundtable. He was involved in four fiberline startups, as well as one recovery boiler startup.

In addition to consulting, he is currently the Chairman of the board of directors for the Perry County Port Authority and Hoosier Southern Railroad.

|

2024 REGISTRATION RATES |

On or Before Tuesday, July 9, 2024 |

After Tuesday, July 9, 2024 |

|

Meeting Registration |

|

|

|

Member |

$1,085 |

$1,194 |

|

Join or Renew and Save |

$1,225 |

$1,382 |

|

Young Professional under 30 Join or Renew and Save |

$1,215 |

$1,323 |

|

Non-member |

$1,539 |

$1,649 |

|

|

|

|

|

Group Meeting Registration, per person (3+ people from the same location) |

|

|

|

Member |

$994 |

$1,112 |

|

Join or Renew and Save |

$1,188 |

$1,307 |

|

Young Professional under 30 Join or Renew and Save |

$1,123 |

$1,236 |

|

Nonmember |

$1,328 |

$1,438 |

Cancellation Policy:

If you find that you have to cancel, your full registration fee will be refunded if TAPPI’s Registration Department receives written notification (fax acceptable at +1.770.209.7206 by (July 9, 2024). Please note: There will be a 50% refund for all written cancellations made after (July 9, 2024) but no later than 5 business days prior to the start of the course (August 1, 2024). Understandably, after (August 1, 2024)no refunds can be issued. Substitutions, however, will be accepted any time without a penalty

| 50% Refund After |

9-Jul-24 |

| 50% Refund Before |

1-Aug-24 |

| No Refund After |

1-Aug-24 |

| Payment Policy: TAPPI requires that all registration fees are paid in full prior to the start of the course. | |

Ways to Save

-

Be the early-bird. Discounts are available for those who register before the early-bird date.

-

Join TAPPI. TAPPI members enjoy discounted rates for this course. If you're not already a member, join us!

-

Bring the team. Group rates are offered for three or more people from the same location.

Hotels near TAPPI Headquarters

Preferred TAPPI Hotel with negotiated TAPPI Rate:

ATLANTA MARRIOTT PEACHTREE CORNERS

475 Technology Parkway NW

Peachtree Corners, GA 30092

www.marriotthotels.com/atlcp

(1.3 mi. from TAPPI)

Rate: $149 + Tax (Jan 1-Dec 31, 2019)

Includes:

-

Complimentary wireless internet throughout hotel

-

Complimentary fitness center onsite

-

Complimentary self-parking

-

Complimentary shuttle within 5 minutes from hotel

-

Marriott Rewards

Reservation Link: Book your corporate rate for TAPPI

Reservation Phone: 800-228-9290 or 770-441-6519 for groups of 10 or more

Rate Code: TAPPI/Technical Association of the Pulp and Paper Industry

___________________________________________________________________________________

HILTON ATLANTA NORTHEAST

5993 Peachtree Industrial Blvd.

Peachtree Corners, GA 30092

www.atlantanortheast.hilton.com

(0.9 mi. from TAPPI)

Rate: $149 + Tax (Jan 1, 2022 - Dec 31, 2023)

Includes:

-

Complimentary wireless internet throughout hotel

-

Complimentary self-parking

-

Complimentary shuttle within 5 minutes from hotel

-

This rate is good for any TAPPI related travel for staff/BOD/Training Courses etc.

Reservation Link: Book your corporate rate for TAPPI

Registration Phone: 1-888-HILTONS OR 770-447-4747 – Rate Code: TAPPI/Technical Association of the Pulp and Paper Industry

___________________________________________________________________________________

HOME2SUITES BY HILTON

5800 Peachtree Industrial Blvd.

Norcross, GA 30071

www.home2suites.hilton.com

(0.8 mi. from TAPPI)

Rate: $119 + Tax (Jan 1-Dec 31, 2019)

Includes:

-

Complimentary breakfast

-

Complimentary wireless internet throughout hotel

-

Complimentary self-parking

-

Hilton HHonors

-

Studio Suites

Reservation Link: Book your corporate rate with TAPPI

Reservation Phone: 770-263-2020 - Rate Code – TAP

___________________________________________________________________________________

HYATT PLACE NORCROSS

5600 Peachtree Parkway

Norcross, GA 30092

www.hyattplace.com

(1.1 mi. from TAPPI)

Rate: $134 + Tax (Jan 1-Dec 31, 2019)

Includes:

-

Complimentary breakfast

-

Complimentary wireless internet throughout hotel

-

Complimentary self-parking

-

Complimentary fitness center onsite

-

Complimentary shuttle within 5 minutes from hotel

-

World of Hyatt Points on every dollar spent

Reservation Link: Book your corporate rate with TAPPI

Reservation Phone: 1-888-568-1562 - Hyatt Place Norcross - Corporate Code - 33999 OR Rate Code – TAPI

___________________________________________________________________________________

Crowne Plaza

6050 Peachtree Industrial Blvd

Norcross, GA 30071

(1.5 mi. from TAPPI)

Rate: $129 + Tacx (Jan 1, 2022 - Dec 31, 2023)

Includes:

-

Complimentary breakfast

-

Complimentary wireless internet throughout hotel

-

Complimentary self-parking

-

Complimentary fitness center onsite

-

Complimentary shuttle within 5 minutes from hotel

-

Meeting Facilities

Reservation Link: Business Hotel in Norcross | Crowne Plaza Atlanta NE-Norcross (ihg.com)

Reservation Phone: 1-877-666-3243

Purchase TAPPI PRESS publications during registration and pick them up at the course to save on shipping.

TAPPI Press is known as an industry leader for publishing reliable and practical publications and training products created and peer reviewed by industry experts for professionals and students alike. This is a great time to refresh or master new skills and restock your corporate or personal library.

TAPPI offers 15% discounted pricing on select TAPPI Press publications when purchased with registration to the 2024 Intro to Kraft Pulping and Bleaching Course. Pick-up on-site and SAVE ON SHIPPING!

This is a great time to refresh or master new skills and restock your corporate or personal library.

The publications featured below are selected for this event.

Kraft Recovery Boilers, Third Edition

View Table of Contents.

Member Price: $ 160 l Non-Member Price: $ 207

NEW! Chemical Recovery in the Alkaline Pulping Processes, Fourth Edition

View Table of Contents

Member Price: $ 150 l Non-Member Price: $ 195

Lime Kilns and Recausticizing: The Forgotten Part of a Kraft Mill

View Table of Contents

Member Price: $ 133 l Non-Member Price: $ 170

Black Liquor Evaporation

View Table of Contents.

Member Price: $ 115 l Non-Member Price: $ 150

Brownstock Washing Fundamentals and Practices

View Table of Contents.

Member Price: $ 157 l Non-Member Price: $ 205

Fundamentals of the Kraft Recovery Process

View Table of Contents.

Member Price: $ 125 l Non-Member Price: $ 152

The Bleaching of Pulp

View Table of Contents.

Member Price: $149 l Non-Member Price: $194

Kraft Pulping

View Table of Contents.

Member Price: $54 l Non-Member Price: $80

Handbook for Pulp & Paper Technologists (Fourth Edition) – (SMOOK Book)

View Table of Contents.

Member Price: $88 l Non-Member Price: $ 113

SMOOK Book is also available in Spanish.

Member Price: $88 l Non-Member Price: $ 113